Drug Delivery Solutions Targeting Specific Therapy Areas

Nipro PharmaPackaging offers a selected range of primary pharmaceutical packaging and medical devices for specific therapy areas.

Primary Packaging Solutions for Emergency Drug Products

Discover our recommended range of primary packaging solutions designed to meet the demands of emergency drug products. Engineered for durability and reliability, our solutions help protect your vital medications when every second counts.

Packaging Solutions for Sensitive Oncology Drugs

Oncology drug products are highly sensitive and complex molecules that are prone to drug-container interactions. Nipro PharmaPackaging offers high-quality primary packaging solutions that meet the challenging requirements of these demanding medicines. Collaborate with our dedicated, cross-functional team of experts to develop the exact packaging solution that your drug product requires, or choose from a selected oncology range.

Drug Delivery Solutions for Anticoagulation Therapy

Ensure the safety and efficiency of your anticoagulant drugs with Nipro's reliable packaging solutions. Our proven expertise accelerates your time to market, delivering seamless integration and stable operations. Trust Nipro for quality and capacity in this critical market segment.

Primary Packaging for Dental Drug Products

Our glass pharma packaging range for dental drug products includes high-quality cartridges. They are designed to ensure the safe and effective use with dental injection devices. The cartridges are made from Nipro’s premium, Type I borosilicate glass tubing, offering excellent chemical resistance and durability to meet the stringent requirements of dental care.

Primary Packaging and Medical Device Solutions for Animal Health Drug Products

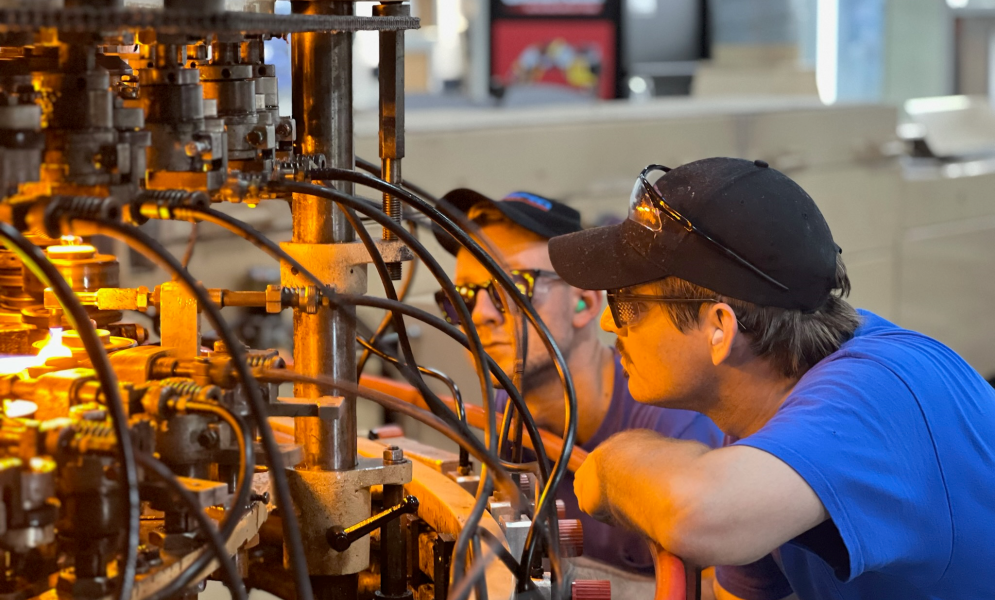

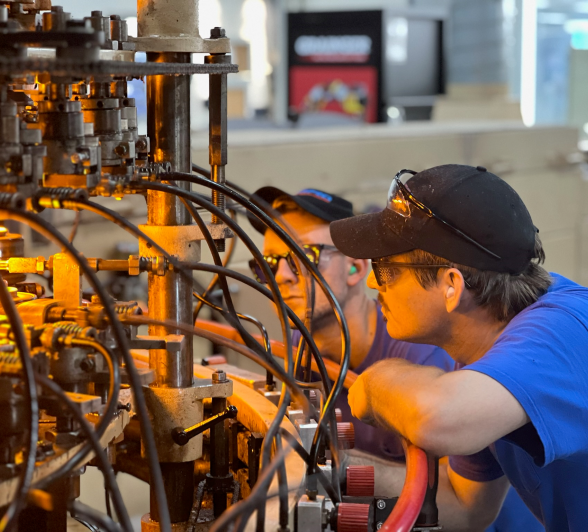

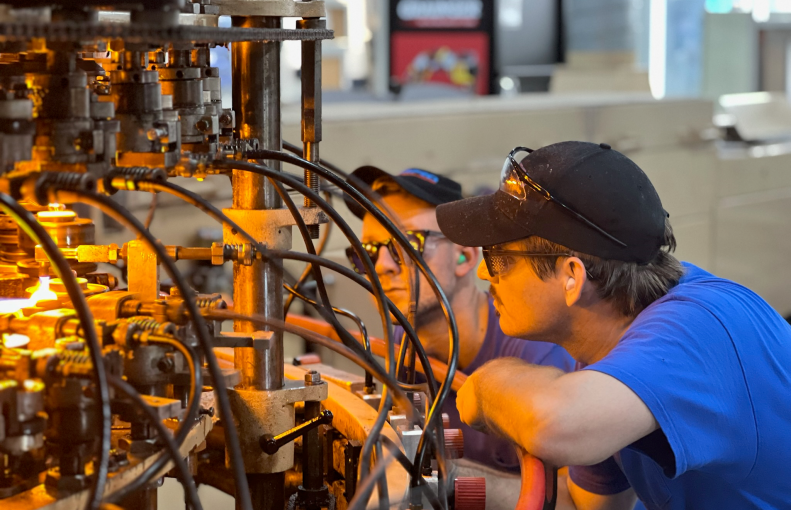

Nipro is a known and trusted partner in providing quality glass packaging solutions for veterinary medicines. Our advanced, standardized production processes guarantee precision and durability in every container. With 15 strategically located production sites across three continents, we offer reliable and efficient supply chains to meet both local and global demands.

Primary Packaging and Medical Devices for Infectious Diseases Drug Products

Parenteral administration of standard and advanced vaccines is essential for widespread immunization against infectious diseases. Nipro produces glass primary packaging solutions specifically designed to meet the stringent requirements for vaccines.

Explore our wide selection of products

Delve into a diverse array of offerings designed to meet your pharmaceutical packaging needs with precision and versatility.

Explore Pharmaceutical Packaging FAQs

Click below to expand and discover commonly asked questions. Explore essential answers about pharmaceutical packaging, including materials, regulations, and sustainability.

Medicines such as vaccines and antibiotics are stored in pharmaceutical packaging. Pharmaceutical Packaging must comply with regulatory requirements set by health authorities to ensure product safety, efficacy, and quality. The packaging protects the pharmaceutical product from physical, chemical, and biological damage during handling, transportation, and storage throughout the entire shelf life.

There are several types of pharmaceutical packaging and each type of packaging serves specific functions in protecting, identifying, and providing information about pharmaceutical products throughout their lifecycle.

- Primary Packaging: The container is in direct contact with the pharmaceutical product, such as bottles, ampoules, vials, blister packs, prefilled syringes, and inhalers.

- Secondary Packaging: Outer packaging that provides additional protection and information about the product, including cartons, boxes, and labels.

- Tertiary Packaging: Bulk packaging used for transportation and storage of multiple units of primary or secondary packaging, such as shipping containers and pallets.

Materials used are chosen based on factors such as product compatibility, protection requirements, regulatory compliance, and cost-effectiveness.

- Plastics: This category encompasses polyethylene, polypropylene, PVC, PET, and HDPE, utilized for crafting bottles, blister packs, and closures.

- Glass: Employed for ampoules, cartridges, syringes, and vials, glass is chosen for its inertness and impermeability.

- Aluminum: Employed for blister packs, foil seals, and closures owing to its barrier properties and light protection.

- Paper and Cardboard: Selected for cartons, inserts, and labels, these materials provide printing surfaces and facilitate information display.

- Laminates: These involve combinations of materials like foil, plastic, and paper to offer specific barrier properties and strength, commonly found in pouches and sachets.

Pharmaceutical packaging serves as a barrier to protect pharmaceutical products from physical, chemical, and biological damage during handling, transportation, and storage. Proper packaging is essential for maintaining the quality and efficacy of pharmaceutical products.

Primary packaging refers to the container that comes into direct contact with the pharmaceutical product. Its purpose is to safeguard the integrity, stability, and sterility of the pharmaceutical product throughout the entire process, spanning from manufacturing, through storage, to its ultimate use.

Various types of glass possess distinct properties that render them suitable for diverse pharmaceutical packaging applications, contingent on factors such as drug compatibility, regulatory requirements, and cost-effectiveness.

- Type I Glass: Borosilicate glass, given its outstanding chemical resistance and low alkalinity, is the preferred choice for packaging injectable medications.

- Type II Glass: Soda-lime glass is frequently used for oral medications such as tablets and capsules.

- Type III Glass: Soda-lime-silica glass is suitable for non-parenteral applications, such as topical medications and ointments.

There are many reasons that glass is a preferred material for pharmaceutical packaging. These include its chemical inertness, exceptional barrier properties against moisture and light, transparency facilitating visual inspection of contents, recyclability, versatility, and compliance with regulatory standards for safety and stability.

Each sterilization method has distinct advantages and limitations. The method chosen depends on factors such as the nature of the product, packaging materials, regulatory requirements, and compatibility with sterilization conditions.

- Autoclaving: Glass containers undergo exposure to high-pressure steam at temperatures typically ranging between 121°C to 134°C for a specified duration, effectively killing microorganisms.

- Dry Heat Sterilization: Glass containers are subjected to elevated temperatures ranging from 160°C to 250°C for a specified duration, achieving sterilization through the oxidative destruction of microorganisms.

- Gamma Irradiation: Glass containers are exposed to ionizing radiation from a gamma radiation source, which damages the DNA of microorganisms and renders them incapable of replication.

- Ethylene Oxide (ETO) Sterilization: Glass containers undergo treatment with ethylene oxide gas in a controlled environment, penetrating packaging materials to eradicate microorganisms. This method requires aeration to remove residual gas.

Ensuring the quality of pharmaceutical packaging involves several key steps:

- Selecting suitable materials that are inert and compatible.

- Validating packaging designs and sterilization processes.

- Ensuring compliance with regulatory standards.

- Implementing quality control testing and assurance systems.

- Conducting packaging integrity testing.

- Monitoring environmental conditions to prevent contamination.

Pharmaceutical packaging guidelines provide comprehensive instructions and standards for the design, development, testing, and use of packaging materials and systems in the pharmaceutical industry. These guidelines aim to ensure the safety, efficacy, and quality of pharmaceutical products throughout their lifecycle, from manufacturing to distribution and use. Some key pharmaceutical packaging guidelines include:

- Good Manufacturing Practices (GMP)

- International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use (ICH) Guidelines

- Regulatory Requirements (e.g., FDA, EMA)

- Pharmacopeial Standards (e.g., USP, Ph. Eur.)

- ISO Standards

- Quality Control Testing Guidelines

- Guidelines for Specific Packaging Types

"RTU" stands for "Ready-To-Use". It refers to products or materials that are prepared and packaged in a way that they can be used directly without requiring further assembly, mixing, or preparation by the end-user.

Overall, glass offers superior protection, stability, sterility, and recyclability, making it a preferred choice for primary pharmaceutical packaging, especially for sensitive medications that require stringent quality control and protection from external factors.

- Chemical Inertness: Glass is chemically inert, meaning it does not react with pharmaceutical ingredients. This ensures the stability and purity of medications, reducing the risk of chemical interactions or contamination.

- Barrier Properties: Glass provides an excellent barrier against moisture, gases, and light, protecting pharmaceutical products from degradation and ensuring their integrity and potency over time.

- Transparency: Glass containers allow for visual inspection of the contents, facilitating quality control, detection of impurities, and accurate dosing.

- Sterility: Glass can withstand high-temperature sterilization methods such as autoclaving, ensuring sterility and reducing the risk of contamination during storage and use.

For information regarding Nipro products, services, and resource material:

| Give us a call +32 15 263 500 |

E-mail us [email protected] |

| Submit a detailed inquiry: Contact per expertise |

View our manufacturing locations: Our global network |